Facility

Product Design

Manufacturing (PDM)

Soft Operations (VMC)

We have a state-of-the-art manufacturing equipment to produce high-quality LED luminaries. Our fully automated SMD Line includes a Yamaha high-speed SMD pick and place machine, an automatic stencil printer, and an 8-chamber reflow oven. This line has the capacity to mount 35,000 LED devices per hour on a variety of PCBs. In addition, we have recently acquired a wave soldering machine to further enhance our in-house capabilities, ensuring that we manufacture good quality drivers and be assured of the final products.

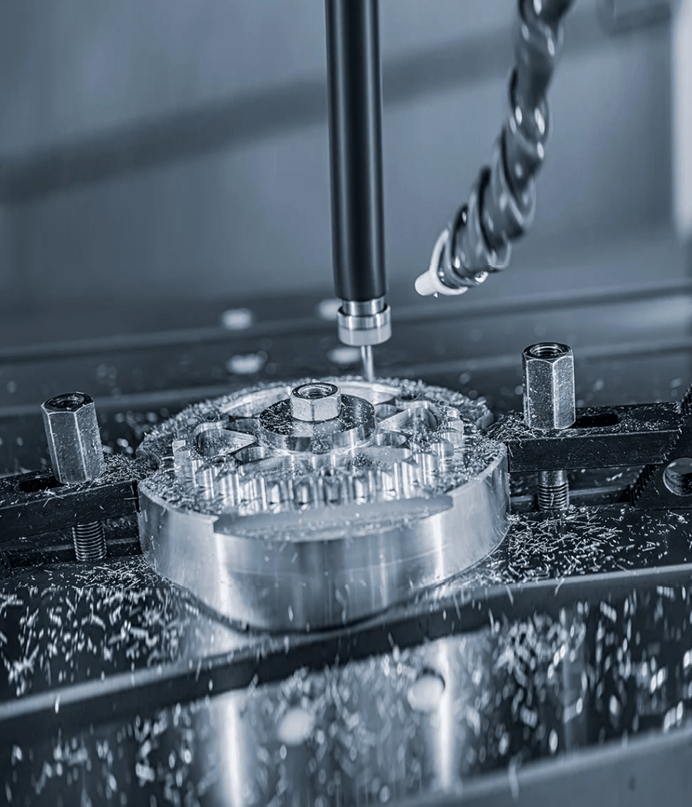

Blank Grinding

Blank grinding is an important process in the manufacturing of gear-cutting tools. Blank grinding is used to shape the specific part of a cutting tool which we typically call Shank and Blank which fits into the cutter body of a Gear Cutting Machine. This operation is also performed frequently for the carbide and oerlikon blanks for dry-cut Machines. The required accuracy for parallelity & perpendicularity in the case of specific blank sizes is up to (+/- 2 Microns). This is why very highly trained manpower and expertise in surface grinding operations is required.

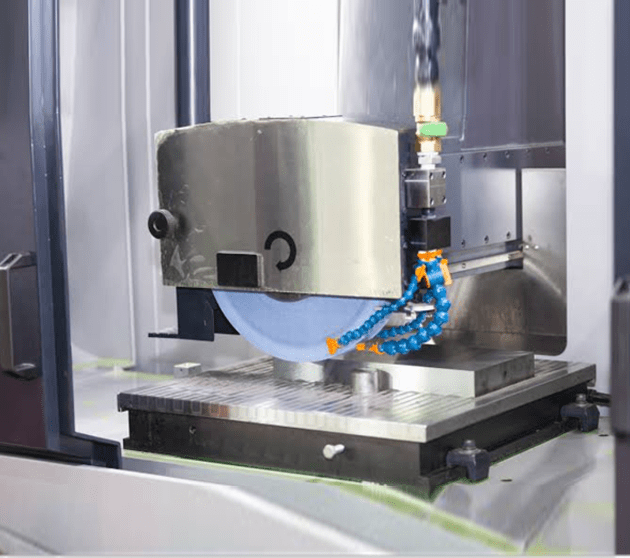

Profile Grinding

Throughout the profile grinding process, the grinding wheel is programmed to meticulously follow the exact profile of the gear tooth that requires cutting. This level of precision ensures that the final product meets the stringent specifications for accuracy, surface finish, and durability.